Navigating Tariffs: Revolutionizing Decision-Making in a Complex World

The Challenges Facing Supply Chains Today

Summary

• Modern supply chains face unprecedented uncertainty and disruption, transforming them into the primary competitive battleground between companies - making traditional planning approaches obsolete and demanding real-time, data-driven decision-making.

• Traditional supply chain technology falls short due to its reliance on historical data, closed ecosystems, and limited analytical capabilities, with 69% of supply chain officers reporting underwhelming results from their tech investments according to PwC's 2024 survey.

• Databricks' Data Intelligence Platform offers a comprehensive solution through AI-powered tools, natural language processing, and proven success stories - helping companies like Shell optimize $1B in spare parts inventory, Walgreens process 40,000 data events per second across 9,000 stores, and Williams reduce TCO by 40% while generating $6M in margin from certified low-emission gas.

If the last few weeks have made us certain of something, it’s uncertainty. Supply chains are being completely reimagined to meet the demands of a new world. Shifting trade policies, spiking input or commodity prices, supplier risks and logistics disruptions - you name the driver of uncertainty - and that’s the new normal for the industry, making supply chains the true battleground for competitive advantage. The real competition now is between supply chains, not individual companies.

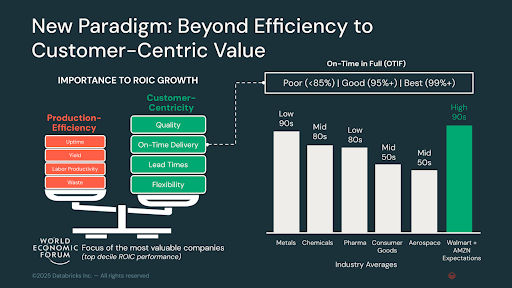

In this new paradigm, companies must build the muscle to continuously improve customer service levels, on-time delivery performance, lead times and do so amidst unprecedented variability and disruptions. Databricks has partnered with leading companies to:

- Manage sharp and sudden volatility – Addressing sudden shifts in customer demand and inputs to optimize supply chain resilience.

- Optimize capacity management – Leveraging AI-driven insights to reallocate capacity and protect high-value production.

- Assess supplier risk - Evaluating supplier reliability, financial stability, and geopolitical exposure to mitigate disruptions and ensure continuity of supply.

- Increase profitability – Using unified data analytics to balance order fulfillment, financial impact, and operational efficiency.

Where Traditional Supply Chain Tech Falls Short

Despite significant advancements in technology, many companies still face persistent challenges that hinder their supply chain performance. Most companies are facing:

- On-Time Delivery Performance Issues: On-time delivery and on-time in full performance are critical success factors, with poor performance leading to severe financial consequences, penalties and customer dissatisfaction.

- Planning-Execution Gaps: A widening gap between planning and execution as disruptive events in supply chains have increased tenfold, making previous business planning approaches obsolete - and requiring accelerated decision making cycles.

- Manual Processes: Prevalence of traditional, error-prone manual processes that lead to missed sales opportunities and shipment delays requiring a shift towards AI-augmented, automated systems that provide real-time insights.

- Sustainability Pressures: The absence of a comprehensive strategy for emissions data in the supply chain as demand for low-carbon products and services is transforming sustainability from a risk mitigation strategy to a powerful profit driver, with customers willing to pay a premium for sustainable options.

To address the business challenges and capitalize on market opportunities, companies must focus on optimizing their supply chains through data-driven solutions, AI-driven automation, and robust emissions tracking across their entire value chain.

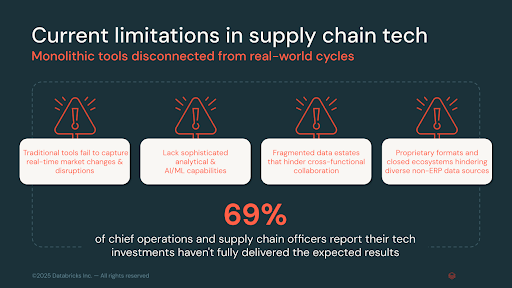

However, traditional demand planning and business software face several challenges:

- Reliance on historical data and periodic reporting, failing to capture real-time market changes and disruptions

- Prevalence of proprietary, closed ecosystems hindering data integration from diverse sources to enhance supply chain planning and execution

- Lack of sophisticated analytical capabilities and machine learning algorithms crucial to improve data quality, complex demand forecasting and supply chain optimization

- Absence of effective data collaboration tools, leading to fragmentation and inconsistent data across departments

Hence, it's no surprise that 69% of operations and supply chain officers say their tech investments haven't fully delivered the expected results (PwC's 2024 Digital Trends in Operations Survey). Chief Supply Chain Officers (CSCOs) are increasingly moving away from these rigid solutions, seeking more open and flexible platforms that offer a holistic view of the entire supply chain and enable real-time, data-driven optimization.

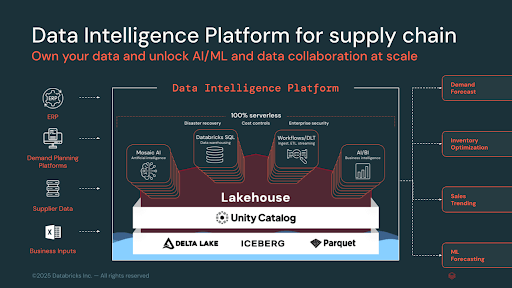

Introducing Databricks Data Intelligence Platform for Supply Chain

Your supply chain is as unique as your company. Why settle for a best-guess approximation solution by someone who doesn't know your business? Build your own unique capabilities with the Data Intelligence Platform.

Manually creating reports to address every supply chain query is no longer feasible or efficient. The sheer volume and velocity of data from global suppliers, logistics partners, and customer touchpoints demand a more scalable and dynamic approach to supply chain analytics.

Databricks offers a comprehensive suite of tools and technologies to revolutionize supply chain management through data-driven insights and AI-powered solutions.

- Databricks SQL and AI/BI Genie empower supply chain analysts by enabling natural language queries and AI-assisted SQL coding, making data accessible to everyone in the organization.

- Mosaic AI’s Multi Model Forecasting framework accelerates large-scale forecasting and planning, crucial for sales, inventory and demand predictions.

- Mosaic AI Agent Framework provides the ability to develop agentic apps that drive autonomous supply chain actions, ensuring accurate, safe, and governed AI applications.

- Unity Catalog Delta Sharing and Clean Rooms facilitate secure data collaboration with partners, while the Databricks Marketplace offers access to valuable third-party data to enhance supply chain analytics.

These integrated solutions enable businesses to make faster, more informed decisions and optimize their supply chain operations in an increasingly complex and data-driven environment.

Real-World Success Stories

- Shell uses Databricks globally to optimize its $1 billion spare part inventory and reduce downtime across upstream & downstream operations globally, providing inventory analysts with recommendations on optimum spare part levels for 3,000 materials across 50 locations.

- Volvo uses Databricks to gain real-time visibility into their massive inventory of over 700,000 parts, enabling them to efficiently distribute these parts worldwide, across the entire chain, from supplier to truck dealer.

- Walgreens leveraged Databricks to optimize their supply chain across nearly 9,000 store locations, saving millions of dollars by right-sizing inventory levels. They now process 40,000 data events per second, enabling accurate inventory forecasting and increasing productivity by 20%. This has allowed pharmacists to avoid expensive out-of-stock situations and spend more time providing personalized care to patients.

- A leading paints and coating company leverages Databricks to automate supply chain forecasting process and gain greater visibility into demand drivers, increasing demand forecast accuracy by 12%, saving of $35M+ in inventory and eliminating $500K+ in overstocking costs per business unit.

- Williams, a natural gas infrastructure company, standardized on Databricks to power high quality datasets for certifying low-emission gas. streamlining data integration from end-to-end production processes such as sourcing, manufacturing, transportation and distribution, and enabling efficient sharing with certification partners. Williams reduced TCO by 40% and was able to monetize their decarbonization efforts, generating $6 million in margin from selling certified low-emission gas, while also advancing their goal of reducing baseline emissions by 50% by 2030.

- HP’s 3D Print division utilizes Databricks' Delta Sharing and AI tools to provide customers with real-time telemetry data on their 3D printing equipment, enabling proactive maintenance, optimized operations, and reduced costs ultimately boosting customer satisfaction and operational efficiency.

Databricks Solution Accelerators

- Distribution Optimization: Optimize transportation costs, predict supply-demand, and improve distribution network performance with pre-built tools.

- Databricks Intelligence Platform for IoT: Using sensor data, machine learning, and GenAI agents to optimize manufacturing operations.

- Safety Stock Management: Optimize inventory levels across the supply chain using machine learning to minimize excess stock, reduce costs, and improve financial flexibility.

- Demand Forecasting: Perform demand forecasting at the part level rather than the aggregate level to minimize disruptions in your supply chain and increase sales, while effectively managing material shortages and avoiding overplanning.

- Route Optimization: Optimize delivery routes, improve profitability, and enhance efficiency in logistics operations.

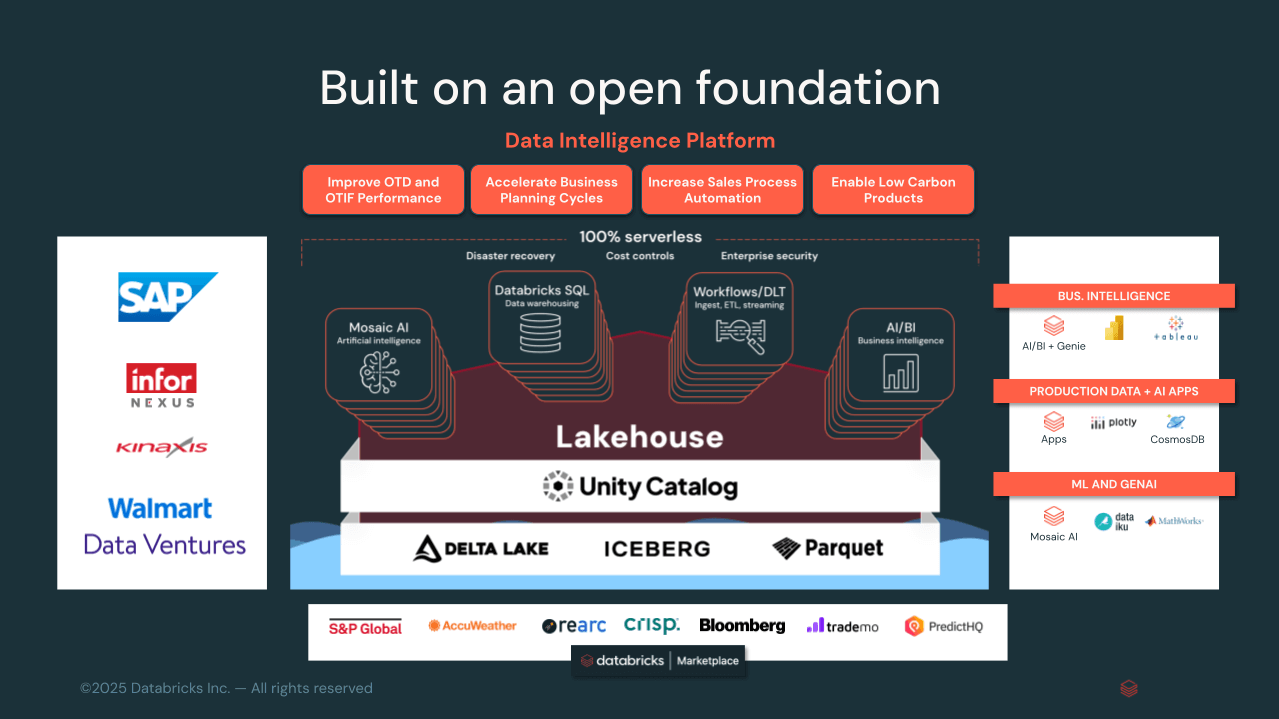

Growing Partner Solution Ecosystem

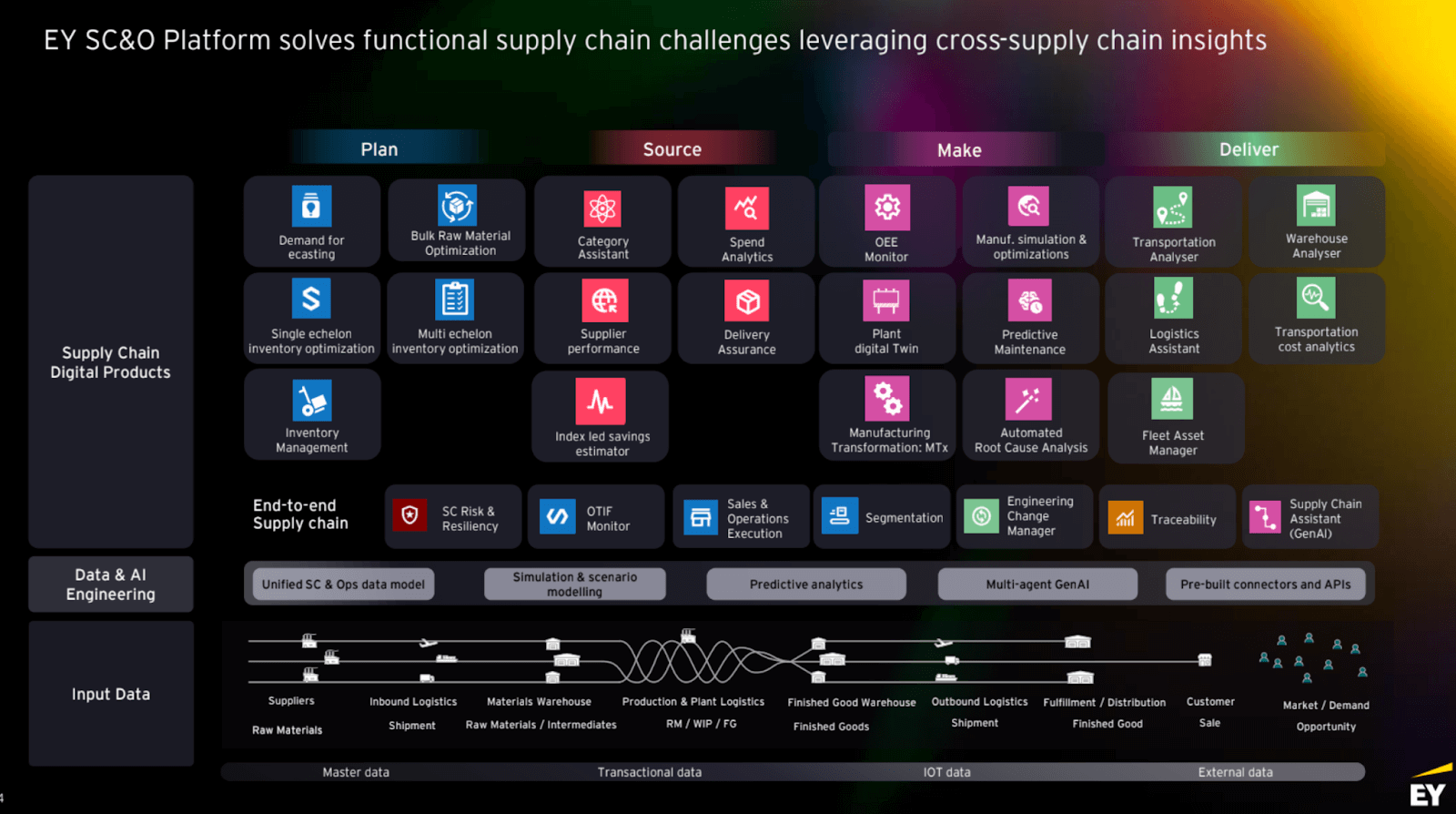

We are excited to have SAP, Infor Nexus and Kinaxis as technology partners, bridging supply chain and enterprise decision makers more effectively. In addition, customers can now enrich their supply chain analytics and AI use cases with proprietary and open datasets from leading data providers such as S&P Global, Accuweather, Bloomberg, Crisp, rearc, Altana, trademo and PredictHQ. Unveiled at NVIDIA GTC 2025, Ernst & Young’s next-generation digital supply chain and operations solution is built on the robust foundation of the Databricks Data Intelligence platform and increases supply chain resiliency against disruptions and offers timely insights through integration with existing systems.

Transform with Data Intelligence

Don't miss this opportunity to revolutionize your supply chain management and stay ahead in today's competitive business landscape. Meet us at the upcoming Gartner Supply Chain Symposium to dive deeper into solutions to shape the future of digital supply chains.

Never miss a Databricks post

What's next?

Manufacturing

October 1, 2024/5 min read

From Generalists to Specialists: The Evolution of AI Systems toward Compound AI

Product

November 27, 2024/6 min read