Rolls-Royce: Harnessing the Power of Databricks Mosaic AI for Image Generation

Rolls-Royce has witnessed the transformative power of the Databricks Data Intelligence Platform in various AI projects. One example is a collaboration between Rolls-Royce and Databricks, focused on optimizing conditional Generative Adversarial Network (cGAN) training processes, that demonstrate the numerous benefits of using Databricks Mosaic AI tools.

For this joint cGAN training optimization project, the team considered using numerical, text and image data. The primary goal was to enhance Rolls-Royce’s design space exploration capabilities and overcome the limitations of parametric models. This was achieved by enabling the reuse of legacy simulation data to drive the identification and assessment of innovative design concepts that satisfy a specified design condition without requiring a traditional geometry modeling and simulation process.

Watch the video: how Rolls-Royce uses cloud-based GenAI to support preliminary engineering design

The joint Databricks and Rolls-Royce team investigated best practices for model configuration, including consideration of the dimensionality limits. The approach included embedding knowledge of unsuccessful solutions into the training dataset to help the neural network avoid certain areas and find solutions faster. Another aspect of the project was handling multi-objective constraints in the design process, in this project we were working with multiple requirements that were potentially in conflict: for example, we were trying to reduce the model weight while also trying to increase its efficiency. The goal was to produce a solution that is broadly optimized, not just optimal for a particular facet of the design.

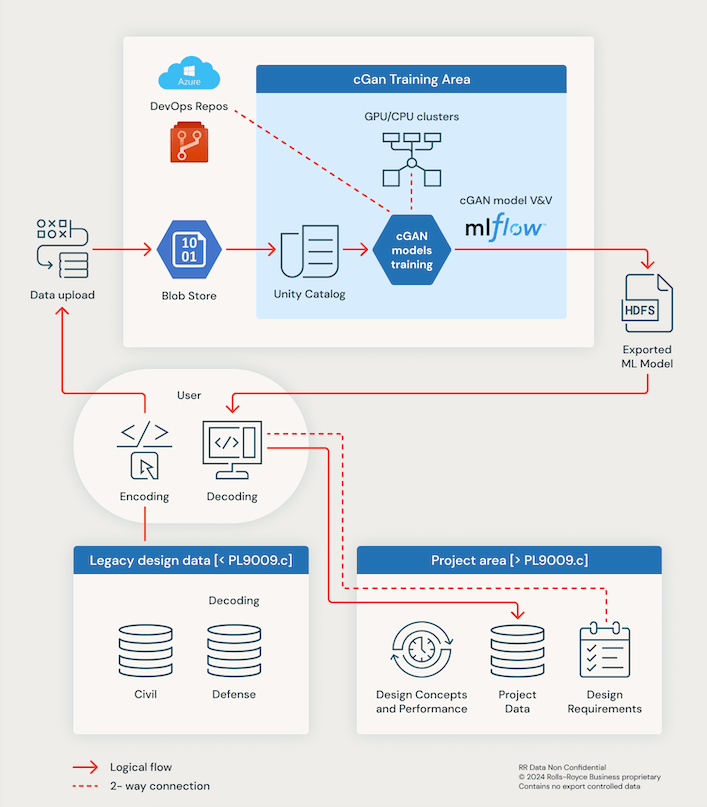

The conceptual architecture for the cGAN project is below.

Big Book of MLOps

Description of the conceptual architecture:

- Data Modeling: Data tables are set up to ensure they are optimized for the specific use case. This involves generating identity columns, setting table properties, and managing unique tuples.

- ML Model Training: the developed ML models are trained using a 2D representation of 3D results from typical simulation studies. This involves embedding knowledge of unsuccessful solutions to help the neural network avoid certain areas and find solutions faster.

- Implementation: Once we developed and optimized models and algorithms, we would then implement them into the product design process

- Optimization: Based on current results, we plan to continually optimize the models and algorithms by adjusting parameters, refining the dataset, and ultimately changing the approach to handling multi-objective constraints.

- Model export: The model trained with legacy data can be exported in a standard format, enabling the option of taking a copy to a secure environment where transfer learning can be conducted with project data characterized by a restrictive Export Control or IP classification.

- Next Steps: Moving forward, we plan to include mechanisms to handle Multi-Objective Constraints. We need to handle multiple requirements that can conflict with each other, which requires developing an algorithm or method to balance these conflicting objectives and arrive at an optimal solution.

There were many benefits to Rolls-Royce in leveraging the Databricks Data Intelligence Platform and Databricks Mosaic AI tools for this project:

- Total Cost of Ownership (TCO): Databricks provides a unified lakehouse architecture that accelerates innovation while significantly reducing costs. As data needs grow exponentially, Databricks is a cost-effective solution for data processing. This is particularly beneficial for large-scale projects at enterprises like Rolls-Royce.

- Faster Time-to-Model: Databricks Mosaic AI tools reduce model training and deployment complexity, enabling faster time-to-model. This is achieved through features such as AutoML and Managed MLflow which automate ML development and manage the full lifecycle of ML models.

- From Experimentation to Deployment: Databricks provides a seamless transition from experimentation to deployment. This is crucial as moving from experiments to production deployments can be challenging.

- Improvement of Model Accuracy: Databricks enables a rapid assessment of model architectures through provisioning access to bespoke packages such as Ray, simplifying the execution of hyperparameter studies, and enabling both scalability (through the execution of more complex use cases that would not be viable through standards machines) and concurrent development (multiple individuals working on or having access to the model). This not only speeds up the model development/testing process but also improves accuracy.

- Data Management / Governance Benefits: The Databricks Data Intelligence Platform provides complete control over both the models and the data. This level of control is crucial for compliance-centric industries like aerospace. The implementation of Unity Catalog establishes a crucial governance framework, providing a unified view of all data assets and making it easier to manage and control access to sensitive data.

- Insights Gained from the Models: The integration of MLflow in Databricks ensures transparency and reproducibility, key factors in any AI project. It allows for efficient experiment tracking, results sharing, and collaborative model tuning. These insights are invaluable in driving business innovation and enhancing productivity.

In conclusion, Databricks provides a robust, efficient, and secure platform for implementing simulation genAI projects. The collaboration between Rolls-Royce and Databricks has demonstrated the transformative power of this new technology. Given the three-dimensional nature of engines, future work will include exploring the transition from 2D models to 3D models.

This blog post was jointly authored by Marco Nunez (Rolls-Royce), Nima Ameri (Rolls-Royce), Shiva Babu (Rolls-Royce), Siddharth Ravichandran (Rolls-Royce), Yashwant Gurbani (Rolls-Royce), Jack Kelleher (Databricks), Marjorie Adriaenssens (Databricks), and Puneet Jain (Databricks).

Never miss a Databricks post

What's next?

Data Science and ML

June 12, 2024/8 min read

Mosaic AI: Build and Deploy Production-quality AI Agent Systems

Data Science and ML

October 1, 2024/5 min read