Solution Accelerator

Build Demand Forecasts at Scale

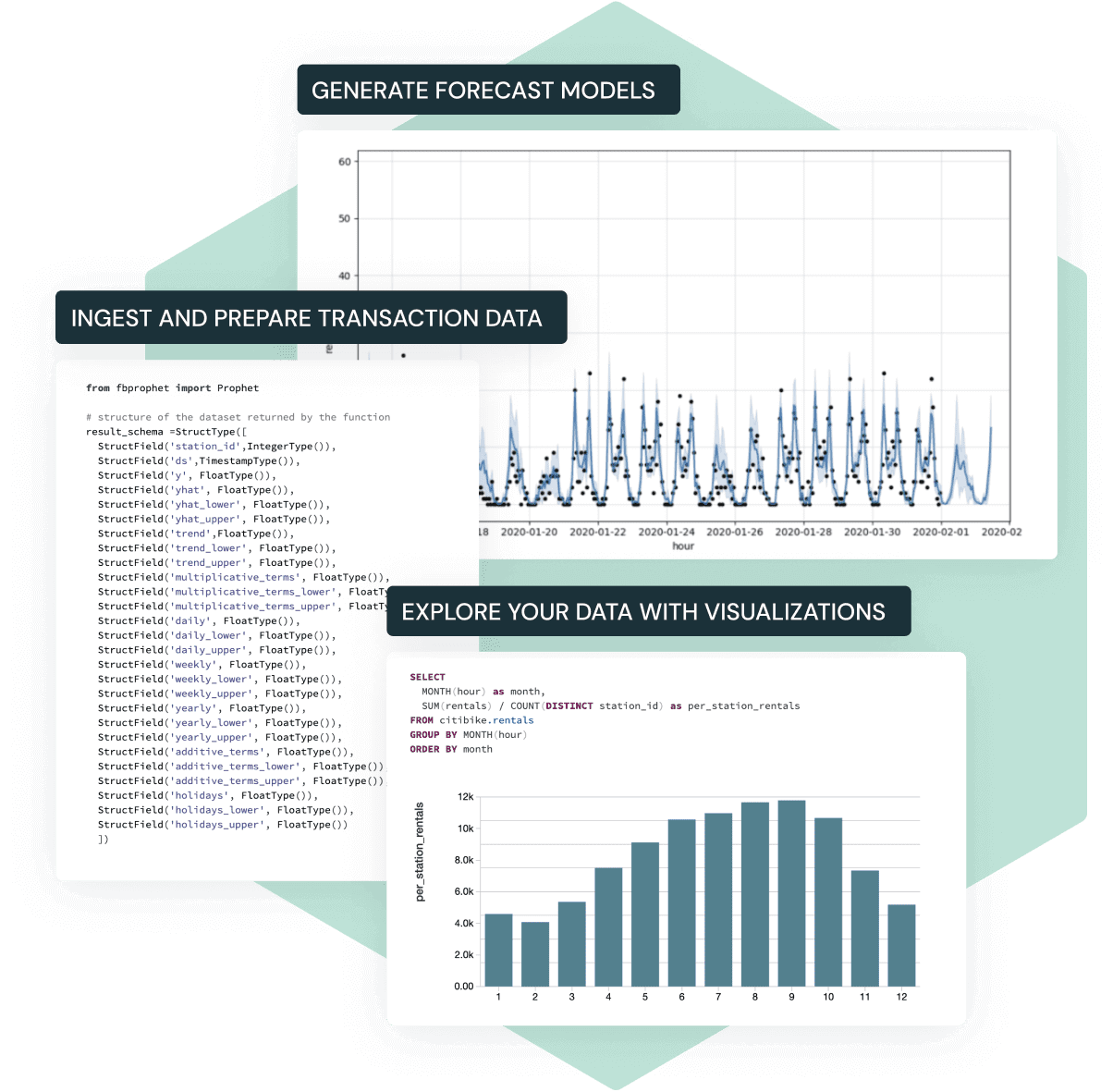

Pre-built code, sample data and step-by-step instructions ready to go in a Databricks notebook

Demand forecasting is the process of leveraging historical data and other analytical information to build models that help predict future estimates of customer demand for specific products over a specific period. It helps shape product road map, inventory production and inventory allocation, among other things.

According to McKinsey, a 10% to 20% improvement in supply chain forecasting accuracy is likely to produce a 5% reduction in inventory costs and a 2% to 3% increase in revenues. In a world where margins are increasingly narrow and critical, this percentage can be make or break. But traditional supply chain forecasting tools have failed to deliver the desired results, limiting success of retailers and manufacturers.

Generate fine-grained forecasts at the retail store level in less time

Perform fine-grained forecasting at the store-item level in an efficient manner, leveraging the distributed computational power of the Databricks Lakehouse Platform. This accelerator helps retailers overcome the technical limitations of legacy data analytics solutions that undermine forecasting accuracy. Instead, perform full forecasts on atomic-level data within tight service windows to do things like:

- Construct a forecast for each store-item combination

- Project demand for each product across stores

- As new sales data arrives, efficiently generate new forecasts and append existing forecasts

- Work in either Python or R

Resources

Explainer Video

Blog

Value Calculator